CAD (Computer-Aided Design) and 3D printing technologies are revolutionizing children’s dental care at Smiles Pediatric Dentistry & Orthodontics in the heart of Los Angeles, where innovation meets high-quality pediatric care.

As a pediatric dentist practicing in West Los Angeles and teaching at the University of Southern California, I am thrilled to share these transformative advancements in modern pediatric dentistry.

These innovative technologies are not only set to transform the future of pediatric dental care, but they are also revolutionizing how we care for children and teens right now and are changing the lives of kids in real-time.

Why Pediatric Dentistry Needs Innovation

Children and adolescents have unique needs. They are not just “small adults.” Their growing mouths require precision, gentle approaches, and sometimes fast solutions. Options for replacing missing teeth and space maintenance have been stagnant for years.

Traditional dental approaches using impression trays, lab-made appliances, and multiple fittings can be uncomfortable, time-consuming, and challenging for children.

Furthermore, the concept of customization has not been considered mainstream in pediatric dentistry.

Restorative solutions, like crowns, come prefabricated and are “ready made” requiring the pediatric dentist to “retro fit” baby teeth to previously shaped crowns made of stainless steel or zirconia.

These solutions are quite different than a perfectly fit, personalized restoration that is designed for a specific child.

What Is CAD and 3D Printing in Dentistry?

- CAD (Computer-Aided Design): CAD software allows us to digitally plan and customize dental and orthodontic appliances, crowns, retainers, and space maintainers with incredible accuracy from a digital oral scan, which is easy to obtain and replaces the need for a dental impression.

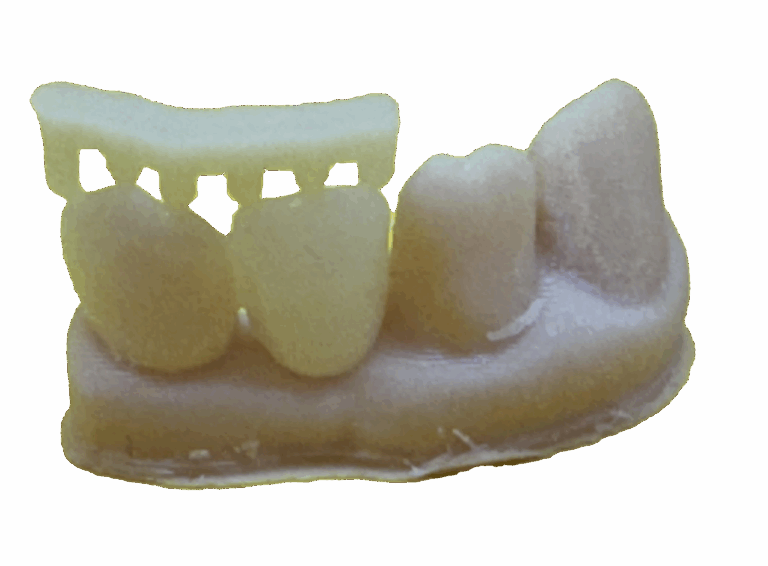

- 3D Printing: Once the design is ready, a special printer creates the appliance, layer by layer, using safe, biocompatible resin materials. This process is fast, precise, reliable, and reproduceable making it ideal for children and teenagers.

3D Printing VS Milling in Dentistry: What is the Difference?

As an adult, you may have experienced “same day” dentistry using milling technologies. Milling remaines a state- of-the-art restorative technology but it has not gained traction in pediatric dentistry due to excessive cost and limited applications on the pediatric dentition.

More importantly, the materials used in dental milling are some of the hardest materials in dentistry. These types of materials do not lend themselves very well to the delicate mouths of small children.

Both milling and 3D printing technologies use CAD software, offer quick turn around times, and are used to create custom dental restorations and appliances. However, the two technologies differ fundamentally in how they produce restorations.

Method of Fabrication:

- Milling is a subtractive process:

- A restoration is carved out of a solid block (often ceramic or PMMA) using high-speed rotary tools.

- It removes material to create the final product, like sculpting from a solid chunk.

- 3D Printing is an additive process:

- Objects are built layer by layer from the ground up using resin or other printable materials.

- The printer adds material only where needed, making it highly efficient and capable of producing complex geometries.

Complexity of Design

- Milling is good for solid, strong restorations:

- Best suited for crowns, inlays, onlays, and bridges that require durability and strength (meaning adult dentistry).

- More limited in internal complexity due to the limitations of cutting tools.

- 3D Printing excels at complex, delicate, or intricate designs:

- Newer resins are showing promising results for restorative options like crowns, that match the needs for young patients.

- Ideal for retainers, space maintainers, aligners, and mouthguards with undercuts or fine structures.

- Enables creation of flexible or multi-material components.

Material Options

- Milling uses ceramics, zirconia, PMMA (Polymethylmethacrylate also known as acrylic or Plexiglas) and composite blocks, which tend to have higher long-term wear resistance making them great for adult restorations.

- 3D Printing materials include resins, flexible polymers, and newer hybrid materials that can be a better match for the growing mouths of pediatric and teenage patients.

Speed & Efficiency

- Milling typically works on one item at a time, which can be slower but delivers a fully finished, strong product.

- 3D Printing can fabricate multiple appliances simultaneously, making it efficient for batch production which is perfect for orthodontics.

Surface Finish and Strength

- Milled restorations generally have a smoother surface and higher strength but cannot deliver the intricate anatomy that 3D printing is now capable of achieving.

- 3D printed restorations may need curing and polishing, but newer printers are closing the gap in surface quality.

3D printing, No-prep designs, Pediatric and Teen Dentistry

The flexibility and innovation possibilities in 3D printing make it a perfect fit for pediatric and teen patients.

Small mouths are better suited to more mailable solutions, like printed resins, rather than ridged restorative options. The ease of reproducibility of 3D printed solutions is also a huge asset to the technology.

Should a child damage or misplace a printed solution, it can simply be reproduced.

Game-Changing Benefits for Kids and Teens

- Same-Day Solutions: From mouthguards to restorations, we can often deliver treatment solution on the same day, reducing multiple visits and fostering efficiency.

- Custom Comfort: Appliances fit well, reducing adjustment time and increasing compliance, especially important for kids who are sensory sensitive or anxious.

- Beautiful Results: With natural-looking restorations and customized appliances, kids and teens feel confident smiling and speaking.

- Space maintenance Innovation: We can now design space maintainers and orthodontic appliances that are low-profile, adjustable.

- Missing anterior: In cases of avulsed, fractured or severely damaged baby incisors and permanent incisors, we are pioneering 3D-printed no-prep solutions to restore function and esthetics with minimal intervention.

How It Works in Our Office

Digital design and technologies are integrated into daily routine at our pediatric dental & orthodontic home, Smiles Pediatric Dentistry & Orthodontics.

Digital oral scans are taken for documentation, child, and parental education and to facilitate pediatric and orthodontic treatment planning.

Oral scans are also used in combination with CAD software to create same-day orthodontic appliances, cosmetic and esthetic dental solutions, and restorations that are individually tailored to the needs of each child or teenager.

Looking Ahead: What’s Next in 3D Pediatric Dentistry?

Further advancements in quality and speed of restorative solutions that reduce overall treatment time and allow using these technologies for the youngest kids in need of restorative care.

Personalized Orthodontics: Imagine clear aligners or expanders 3D-printed on site, fully customized to a child’s or teen’s digital scan. Or growth-adaptive devices that adapt to growth over time, reducing the need for appliance replacement.

Final Thoughts

Innovations in CAD and 3D printing are making pediatric dentistry more personalized, efficient, and minimally invasive. They are also enhancing patient experience with easy, kid-friendly appointments.

As a mother, a pediatric dentist, and a true advocate for modern dental technology, I believe that 3D printers will be playing a significant role in pediatric dental offices in the coming years. I am proud to be a leader in this pediatric dental digital transformation.

If your child needs gentle, leading-age dental care and unique, state-of-the art dental solutions, we would love to welcome you at our practice and show you the possibilities firsthand.